Summary: Among the most popular shoe sole materials we know are Rubber, TPU, TPR, EVA, and Phylon, and they are quite important in footwear because most of our shoes include these materials. But what is Carbon Fiber Plate in Shoes? In this article, we will discuss the properties of this innovative material, how it is made, its benefits, different types of carbon plates, and everything related.

Table of Contents

Who Invent the Carbon Fiber?

Before knowing what is Carbon Fiber Plate in Shoes, we should first know who is the first person to invent carbon fiber.

Sir Jo⁃seph Wilson Swan (1828-1914), an English chemist and physicist, invented the incandescent lamp with a platinum wire as the luminous body. To solve the problem that platinum wire was not heat-resistant, Swan used a thin strip of carbonized paper instead of platinum wire. In 1860, Swan invented a semi-vacuum carbon filament lamp with a carbon paper strip as the luminous body, which was the prototype of the incandescent lamp. Swan invented the incandescent lamp 20 years earlier than Thomas Alva Edison (1847-1931). Because of the immaturity of vacuum technology at the time, the lamp did not have a long life. the late 1870s, vacuum technology has been developed, Swan invented a more practical incandescent lamp, and in 1878 was granted a patent for the incandescent lamp.

In 1879, Edison bought the patent and invented the incandescent lamp with carbon fiber as the luminous body. 1892 Edison invented the “incandescent bulb carbon fiber filament manufacturing technology and obtained a U.S. patent (patent No. 470925). It can be said that Edison invented the earliest commercialization of carbon fiber.

Yes, we know that Edison became the first person to use carbon fiber commercially, but what exactly is carbon fiber Plate in shoes?

What is the Carbon Fiber Plate in Shoes?

In the early 1950s, due to the development of rockets, space and aviation, and other cutting-edge technology, the urgent need for new materials with high specific strength, high specific modulus, and high-temperature resistance, in addition, the use of precursor fibers as raw materials by heat treatment process can be made into carbon fiber continuous filament, this process laid the foundation for the industrialization of carbon fiber.

Carbon fiber is mainly composed of carbon elements and has the characteristics of high-temperature resistance, friction resistance, thermal conductivity, and corrosion resistance. Its shape is fibrous and its texture is soft, and it can be processed into various fabrics. The density of carbon fiber is very low, so the specific strength and specific modulus are very high. The diameter of carbon fiber is only 5 microns, equivalent to one-tenth to one-twelfth of a hair, but is more than four times stronger than aluminum.

Due to its advantages of lighter mass, tougher, more flexibility, and good fatigue resistance, the carbon plate was then used in basketball shoes and soccer shoes to prevent injuries to players in sharp stops and turns, rapid acceleration, changes of direction, and other movements, and to stabilize the shoe and support the arch against torsion.

Why Does the Carbon Fiber Plate in Shoes Help People Run Faster?

When carbon plates are used in racing shoes, they do more than simply strengthen the midsole structure and provide arch support stability. They also do something even more amazing: increased flexibility, powerful thrust, improved running efficiency, and energy savings for the runner, and these exciting descriptions are not exaggerated. Many of those who wear them have running speed legends.

In the 2017 Broken Two Challenge, Kipchoge ran 2 hours and 25 seconds wearing Nike’s first carbon plate running shoes VaporFly Elite, causing an uproar, and since then carbon plate running shoes have entered our field of vision.

Sounds good? Not so fast, let’s dive into why carbon fiber truly makes us run faster:

Because the basic principle of carbon plates to improve running efficiency is to reduce the flexion of the metatarsophalangeal joints during running, when the foot lands – lifts – and pushes off the ground, the front-to-back flexion of the entire midsole of the running shoe is very small, relying more on the lifting force of the Achilles tendon and leg muscles.

Mechanically speaking, the process of landing – pushing off and lifting up – is equivalent to the process of prying a lever. The fulcrum of the lever is the heel bone – in normal running shoes, the moment you push off the ground (pry the lever), the metatarsophalangeal joint flexes, and this behavior absorbs (wastes) energy. At this point, the resistance arm distance is the distance from the heel bone to the front of the metatarsal bone, which is relatively short; when wearing carbon fiber running shoes, the metatarsophalangeal joint flexes less (reducing energy consumption), at which point the resistance arm extends to the toe bone, which is a longer distance.

The longer distance of the resistance arm requires more force (Achilles tendon and leg/hip lift) to pry the lever, with the result that as little energy as possible is wasted in each step between landing and leaving the ground, and the stride length becomes longer because the lift is more pronounced.

As a result, when you first put on carbon racing shoes, your running posture will usually change strongly: you’ll feel the carbon plate more clearly as you stride forward, you’ll find it harder to flex your metatarsal toes despite the soft midsole, you’ll get more accustomed to pushing the midsole with your forefoot, and your stride length will feel significantly greater compared to every day.

Amazing? Let’s take a look at how Carbon Fiber is made in Shoes now.

How Are the Carbon Fiber Plates of the Shoes Made?

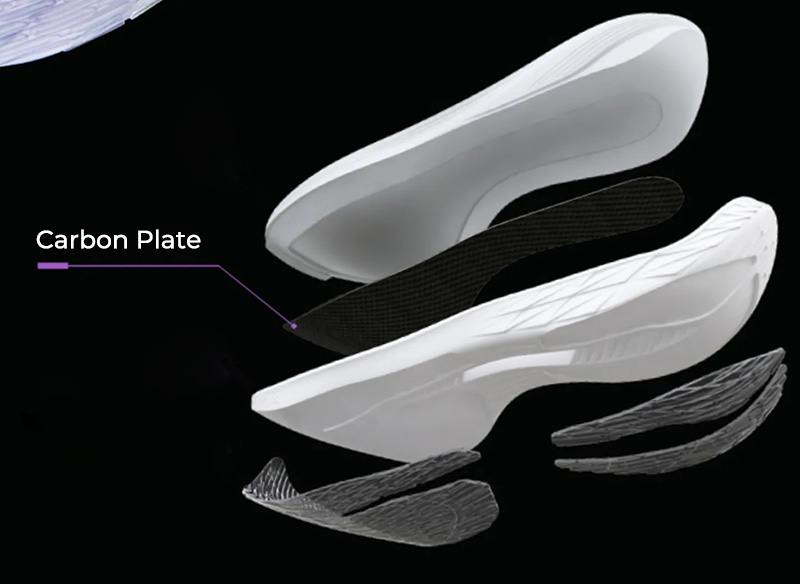

What we call “Carbon Plate” should actually be called carbon composite, because it is a composite material formed by bonding epoxy resin and carbon fiber filaments, which is very similar to fiberglass mixed with epoxy resin, but stronger. The manufacturing process of carbon fiber filaments is very complex and requires a very high level of technology.

Simply put, a polymer called polyacrylonitrile is drawn into a filament, which is then carbonized in nitrogen at 2,500 degrees Celsius. Carbon sheets are first formed by weaving carbon fiber yarns into cloth, then soaking and cooling them with liquid epoxy resin.

Let’s take a quick look at how the carbon fiber plate for the shoes is made with the photos below.

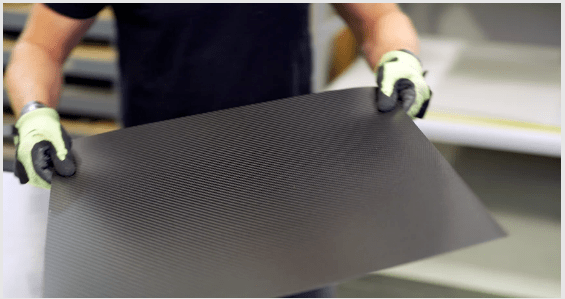

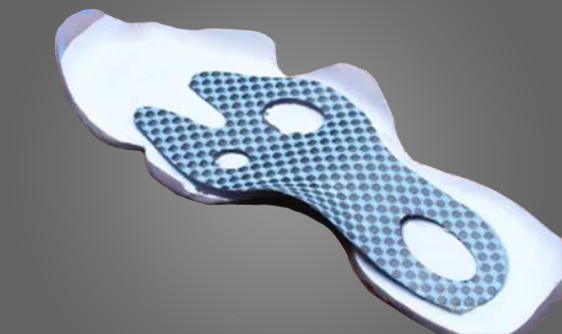

Step 1: Specific layers of woven fabric, prepreg, and polymer film are stacked together to form the panel.

Step 2: Solidify the panel in a heated press.

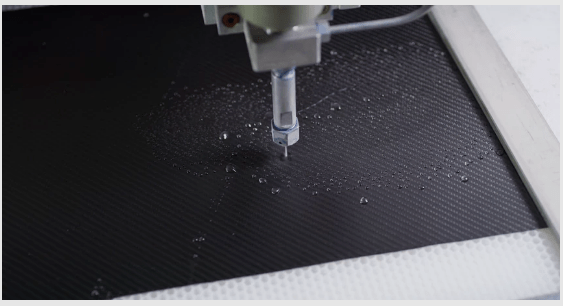

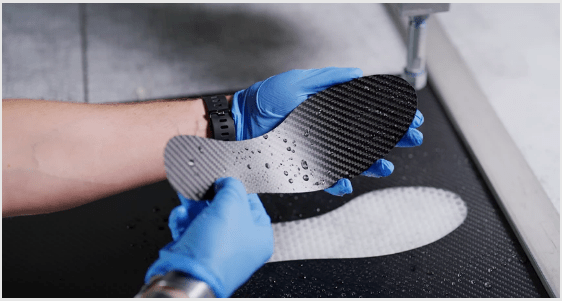

Step 3: Cutting off specific components from cured panels by spraying water

Different Types Of Carbon Fiber Plates in Shoes

The carbon plate shapes are divided into four categories according to the different motion properties – full sole 2D carbon plate, full sole 3D carbon plate, partial 2D carbon plate, and partial 3D carbon plate.

No.1 Full Sole 2D Carbon Fiber Plate

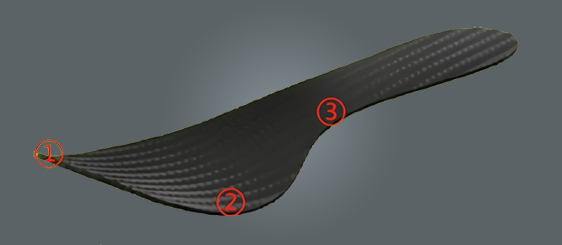

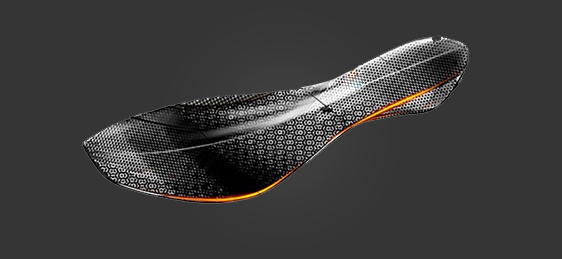

S-type full sole spade carbon plate, because the shape of the spade is like a spoon, some manufacturers may be called spoon type, although the name is different, but the principle and material are the same.

Because the shape of an S-shaped carbon plate is designed according to the human foot shape.

- Toe bone position is slightly cocked.

- Metatarsal position is down (that is, the bottom of the spoon).

- Arch position is higher than toe bone.

Therefore, when running forward in a straight line, after the foot is stepped down, the carbon plate itself is rigid to provide counter-thrust and return to the whole foot’s explosive force.

No.2 Full Sole 3D Carbon Fiber Plate

Full-sole 3D carbon plate not only helps to propel the roll, but also ensures stability, while the inner and outer carbon plates of the heel and forefoot have a certain bulge, and the 3D carbon plate of the heel gives enough support to the foot to deal with complex terrain and better help runners improve their speed. Let’s say, a full sole 3d carbon plate allows for maximum integration of speed and protection!

No.3 Partial 2D Carbon Fiber Plate

The placement of the partial sole carbon plate is a good reflection of the differentiation and cost control and is generally placed in the forefoot or arch position, which also provides the corresponding stability and propulsion.

Forefoot Carbon Fiber Plate

The forefoot carbon plate is more suitable for forefoot or full sole landing runners as the forefoot carbon plate curvature structure allows runners to have more rolling feeling and more energy saving.

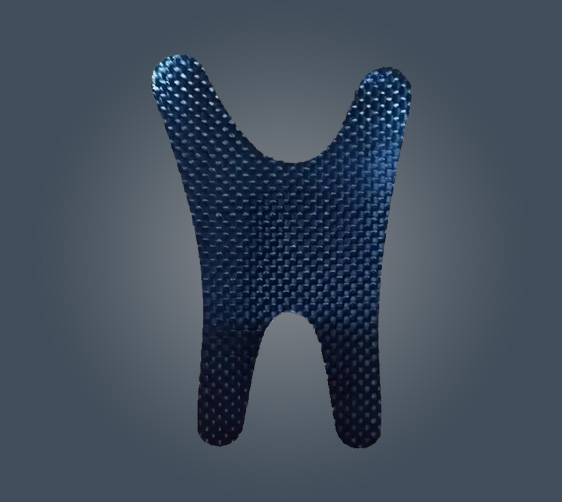

Arch Carbon Fiber Plate

The arch carbon plate is mainly used in basketball shoes/running shoes, due to the high landing and forward rolling properties of basketball and running sports, the damage (or exercise) to the foot arch is larger, and then the support and protection of the foot arch carbon plate such a need to offer the strong support and protection.

Rearfoot Carbon Fiber Plate

Rearfoot partial carbon plate, mainly to play the role of stabilizing the heel, and ensure the heel is not easy to shake during the running process.

Left and Right Side Carbon Fiber Plate

The left and right side strip carbon plate is mainly used in trail running shoes, as trail running is more complex than road running, and most of the terrain is sand and gravel, due to this specificity environment, the carbon plate needs to meet the adaptability to the outdoor terrain variability, and hardness support at the same time.

Two long X-shaped 2D carbon plates are built into the left and right sides of the midsole, just like the independent suspension system of a car, protecting the front and rearfoot in four directions.

No.4 Partial 3d Carbon Fiber Plate

The three-dimensional carbon plate is mainly used in the side or arch position of the basketball shoes to match the basketball players’ various breakthroughs, direction changes, sharp stops, jump shots, scrambles, retreats, and other actions to protect and reduce the excessive load on the arch, resist torsion, reduce ankle injuries, besides, the shoes are not easily deformed.

Generally, there is some climbing flexion at the arch position, and then some extension of the forefoot and hindfoot.

Conclusions

In this article, we have walked you through everything related to carbon fiber and carbon fiber plates in shoes, the benefits, and manufacturing processes, and different types of carbon fiber plates in shoes. In addition, the carbon fiber plate material is by far the best in the industry, due to its lightweight, capricious and strong properties.

Let’s make it even clearer, to judge whether the configuration of a sports shoe is good or not, having a carbon fiber plate is a big plus and can attract more consumers to buy this shoe. The main role of the carbon fiber plate in shoes is anti-torsion, that is, to prevent the midsole of the sports shoes/sneakers from twisting strongly. This composite material allows you to maintain the stability of the shoe when you make a dramatic breakthrough in direction and is able to provide effective thrust for athletes to improve reaction time and speed up their running speed.

Subscribe to Know First

Keep you updated with our latest news and products.